The ins and outs of flexible packaging

Often, before you see a product, you see its packaging. It's the eye-catcher on a shop shelf, the colour-setter on an exhibition table... In short, it's the packaging we choose for reasons that are as functional as they are commercial. Originality, ergonomics, quality, environment friendly... Packaging is also, and above all, the key to a product's success. In this article, we reveal the secrets of the most popular type of container on the market: flexible packaging. Where does it come from and what does it look like? How do you choose the flexible packaging that will make all the difference? Our complete guide to packaging that reflects your identity!

The history of packaging: from preservation to marketing

The origins of packaging

The need to preserve products is nothing new. In prehistoric times, human beings were already making containers to store foodstuffs. But how did we go from skin containers to polymer bottles? The answer lies in 10,000 years of trial and error and one pivotal point: the Industrial Revolution. Since 1809, with the appearance of the glass jar, there has been an explosion of inventions on the industrial packaging market. From wood to cardboard, from tinplate to aluminium, from solid to flexible, we are now capable not only of protecting and transporting all possible materials, but above all... of showcasing them in an ultra-competitive world!

Why choose flexible packaging?

Soft or flexible packaging, as opposed to rigid packaging, takes the form of malleable pouches adapted to the product to be preserved and transported. Flexible packaging is used in all industrial sectors, including cosmetics, food, and pharmaceuticals, and in every conceivable format. This is especially the case today with digital sealing and 3D printing technologies, which allow to create unique packaging in record time. A sealed aluminium pouch in the shape of a bottle for a sample of shampoo? A stand-up pouch with a resealable zip filled with dog food? Whatever your needs, flexible packaging bends over backwards to suit you:

- It takes up very little space: in transport and in your warehouses, because it uses less material and is therefore more environmentally friendly

- It's big: in people's minds, because it attracts the consumer's attention and clearly informs them of the contents

- It's practical: ergonomic and light in the hand, adapted to the use and protection of your products.

- It's designed to reflect your image: polymer, aluminium, or cardboard, square, round or star-shaped... print your colours on customised pouches for a unique look!

Flexible packaging standards

Flexible packaging has the advantage of being extremely versatile: it can be adapted to any type of product and any type of material (solid, pasty, or liquid). But for optimum design, you need to choose:

- The material: cardboard, paper, polymer, aluminium, etc.

- The shape and type of base: standard stand-up, three-seam, cushion, etc.

- Additional options: spout, nozzle, valve, etc.

- Exterior printing: digital, offset, flexographic, etc.

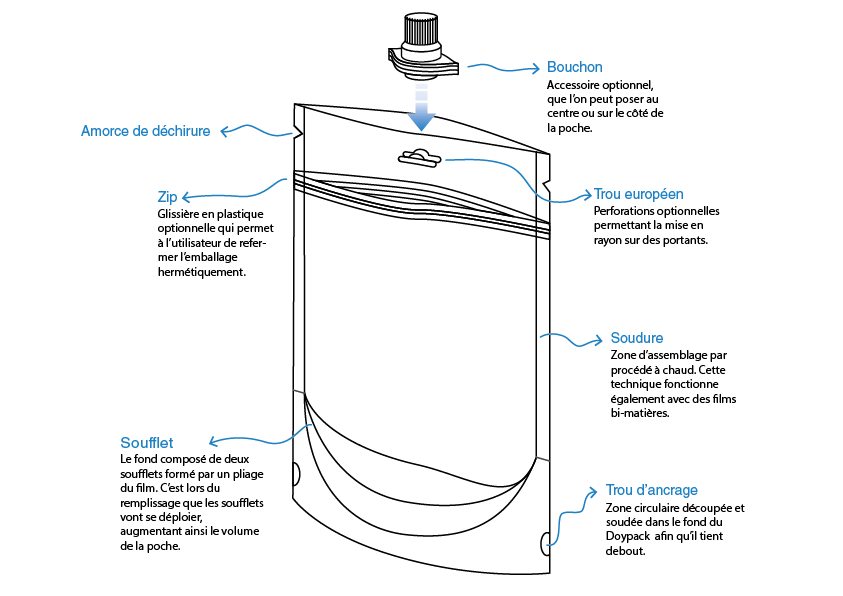

The Doypack, or stand-up pouch

In 1962, Louis Doyen, CEO of Thimonnier, combined the best of rigid packaging (stability, aesthetics) with the best of flexible packaging (small size, ease of manufacture) to create the famous stand-up pouch, also known as the Doypack Doypack.

This great packaging classic is easy to recognise in the trade: it's a lightweight, ergonomic sealed pouch that stands upright, offering a communication face on both the front and the back. Doypacks are mainly manufactured in multi-layers to protect the food or cosmetic products inside. It is available in a variety of formats, the main features of which are as follows:

- Materials and barrier: depending on the use and preservation quality of the product contained

- Side gussets or bottom gusset: depending on volume and appearance

- Oval or K-shaped base: depending on volume

- External printing: often flexographic or heliogravure

- Closure: open or closed pouch, tear starters, nozzle, single or double zip, spouts with boat shape or full-face bases, etc

All kinds of accessories can also be added, such as :

- Handles for consumer use

- Round or European holes for hanging the container on a display stand

- Transparent windows for viewing the interior

- Valves to preserve flavours (especially coffee)

- Straws (for fruit juices, etc.)

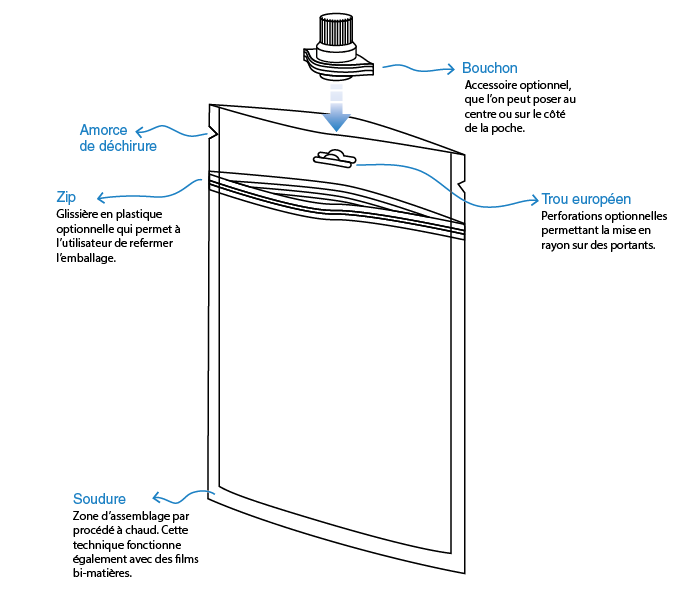

3-seam pouch

Unlike the Doypack, the three-seam pouch is completely flat. As its name suggests, it is sealed on three sides (or via a back seal) and opens on the fourth. It is widely used in the food and pharmaceutical industries. All kinds of accessories can be added to it, and it can be designed using the following components le sachet trois soudures:

- Materials and barrier: depending on the use and preservation quality of the product contained

- External printing: often flexographic or heliogravure

- Closure: open or closed pouch, tear starters, nozzle, single or double zip, spouts...…

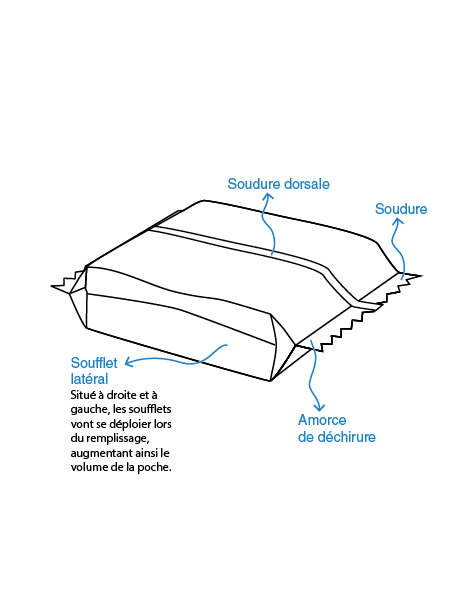

The cushion pouch

Of any size, thickness, and strength, the cushion pouch is sealed on all four sides. Either it is designed to be opened only once (e.g., a pouch of sweets), or it comes with a spout, allowing it to be placed in a carton or barrel. In the latter case, the content is either liquid or pasty (e.g., wine box application). They are often available in mono-material polymer or paper. est scellée sur les quatre côtés. Soit elle est conçue pour s’ouvrir une seule fois (ex : sachet de bonbons), soit elle s’accompagne d’un bouchon, ce qui permet de la positionner dans un carton ou un fût. Dans ce dernier cas, le contenu sera liquide ou pâteux (ex : application pour cubi de vin). On en trouve souvent en mono-matériau plastique ou papier.

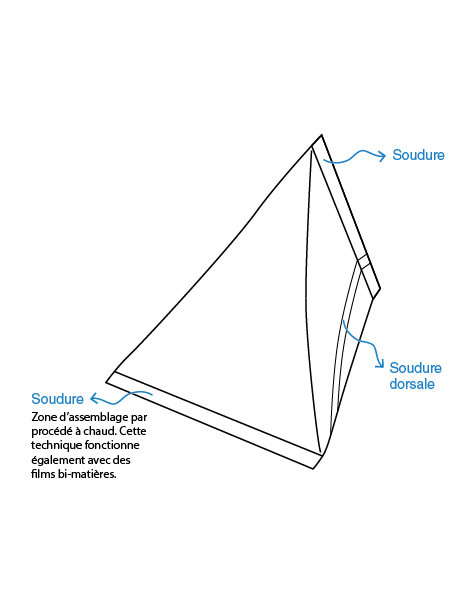

The Berlingot pouch

In 1951, Swedish industrialist Ruben Rausing came up with an invention that revolutionised drinks packaging: the Berlingot. This flexible, tetrahedral-shaped packaging was originally designed to store and transport all types of liquid (particularly milk). Technically speaking, the Berlingot is sealed at one end, filled with the liquid product, then sealed on a perpendicular plane to close the packaging. To open it, you have to cut off a corner. They are now used in the food industry, for hygiene products, and detergents. Its design can vary according to various options: spouts, European holes, nozzles, etc…

Specific flexible packaging

Do you have a specific packaging idea in mind and standard packaging formats just won't do? There are many solutions for tailor-made projects!Environmentally-friendly packaging

Reusable or biodegradable packaging is the choice many companies have made to lead the environmentally-friendly packaging movement. Today, we see a lot of packaging made from kraft, wood, reed fibre, or corn starch. Is this a step backwards? More like a reuse of primitive materials in favour of more environmentally-friendly packaging. You'll find examples from all the major brands: emballages réutilisables ou biodégradables, c’est le choix qu’ont fait de nombreuses entreprises pour mener le mouvement de l’éco-emballage. On retrouve aujourd’hui beaucoup de packaging en kraft, en bois, en fibre de roseau ou en amidon de maïs. Un retour en arrière ? Plutôt une réutilisation des matériaux primitifs afin de privilégier un emballage plus respectueux de l’environnement. Vous trouverez des exemples chez toutes les grandes marques :

- Daddy, with its Doypack packaging made from raw kraft paper for its range of powdered sugars

- Vittel, with its 100% recycled polymer water bottle

- The children's clothing brand Monday's Child, with its cardboard packaging that doubles up as a doll's house

Would you like to adopt a sustainable approach? Flexible packaging is an excellent solution to help you make this ecological transition. It visually communicates your CSR commitment to consumers. For example, choose a mono-material container, an optimised volume, and a low-energy manufacturing technology to facilitate recycling and limit material losses.

100% tailor-made packaging

When you know that it takes consumers less than thirty seconds to choose a product in a supermarket, it's in your interest to stand out from the crowd with attractive packaging. As well as the price and the product's position on the shelf, potential consumers will look at the packaging. Its appearance, information, and use are all criteria you need to think about.

Do you want to attract attention with an original shape? Do you want to display an environmentally-friendly material? To create a unique and memorable brand identity, why not design a tailor-made flexible packaging? Thanks to digital printing, your containers can be tailor-made according to your requirements and identity, in one-off or small production runs. Design "out of the box" packaging to make all the difference! vos contenants sont personnalisés selon vos souhaits et votre identité, en exemplaires uniques ou en petite série. Créez un packaging “out of the box” pour faire la différence !