Production of a variety of shapes

with a single tool

Changing the shape of packaging on traditional production machines requires specific tools for each shape, leading to additional tooling costs as well as downtime for tool changes.

DigiPlus avoids these disadvantages: it is a technological building block that can be implemented on existing flexible packaging machines to make them more flexible in terms of the shape of the pouch produced.

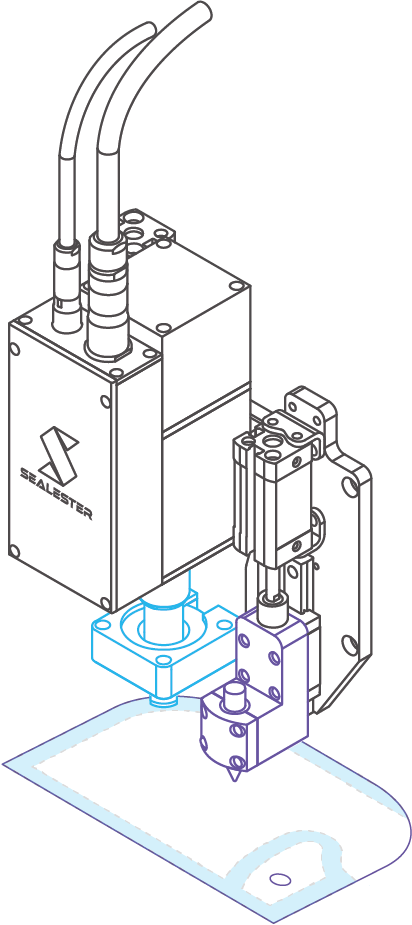

DigiPlus is based on the sealing principle developed by SEALESTER: a sealing tool moves over the films to seal them along a trajectory predefined by the operator. At the end of the shaping line, this option adds a special sealing and/or cutting shape to the packaging produced, using a single tool.

Reducing MOQs (Minimum of quantity)

Traditionally, each shape corresponds to a specific tool. To be cost-effective, production minimum order quantities (MOQs) are therefore increased. The DigiPlus solution eliminates the need for specific tooling for each shape, allowing for reduced MOQs on production machines while maintaining shape flexibility and variability. This enables a range of pouches with a low MOQ (for example, 5,000) while still being profitable.

The materials

To reduce the environmental impact of packaging, new eco-friendly materials are being introduced to the market. Depending on their composition, welding these materials can present a significant challenge. In our technology, the heat required for welding is applied in a controlled and localized manner, allowing for effective sealing of certain materials that are sensitive to overheating.