Since the commercial success of a product also depends on its packaging, you need to make the right choice of design and manufacture. Recycled cardboard boxes, mono-material paper bags or printing with vegetable-based inks? For several years now, packaging has been going greener to adapt to environmental constraints. For many consumers, environmentally-friendly packaging is now as much a criterion of choice as the quality of the product inside So how do you combine the primary function of packaging with the expectations of your customers? We'll help you choose the right packaging to preserve and sell your products properly! est désormais un critère de choix, au même titre que la qualité du produit à l’intérieur. Mais comment combiner la fonction première de l’emballage et les attentes de vos clients ? On vous aide à bien choisir votre packaging pour conserver et vendre vos produits comme il se doit !

The function of packaging

To design packaging that suits your product and your corporate identity, you first need to ask yourself these two questions: what is the purpose of packaging? What are the different types of packaging? Here are our answers.

Definition of packaging

Packaging is used to preserve, transport and store liquid, pasty or solid products. As far back as prehistoric times, mankind designed its own packaging to preserve foodstuff. Although hygiene and marketing concepts have since been integrated into the concept, the primary function of packaging remains the same in today's society: to protect the contents. It also serves to inform the consumer.

There are a multitude of materials and manufacturing processes that any company can use: from polymer to fine paper-cardboard, from bagging machines to digital printing... There's an abundance of choice to bring the packaging of your dreams to life!

Primary, secondary, and tertiary packaging

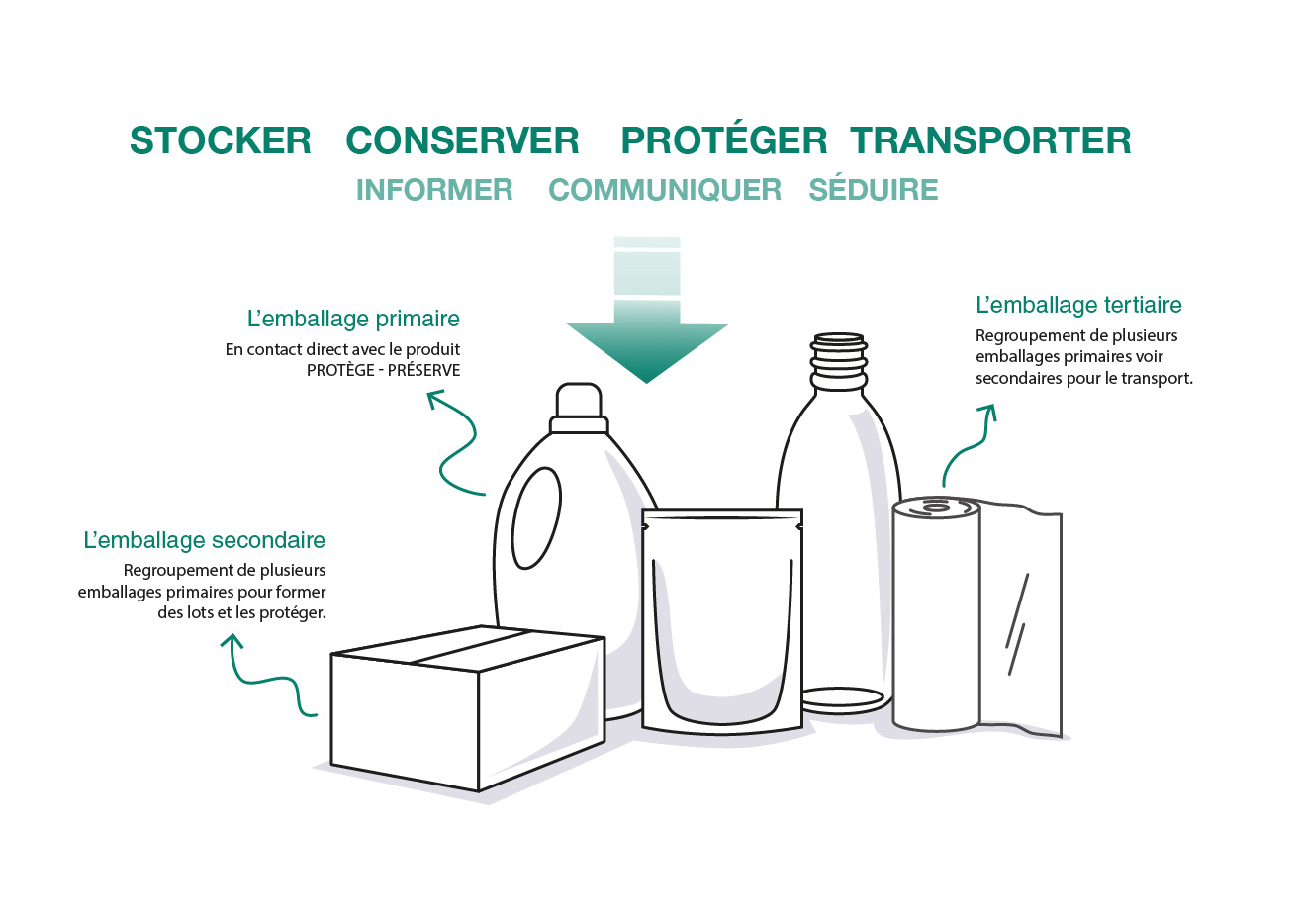

In the world of packaging, there are different levels of packaging. We talk about primary, secondary, and tertiary packaging :

Primary packaging (or consumer unit): directly in contact with the product, which it protects from external damage ;

Secondary packaging (or sales unit): this groups together several primary packages to act as a dispatch pack. It can contain additional protection (cushions, reinforcements, etc.).

Tertiary packaging (or handling packaging): this groups together large quantities of secondary packaging for transport between two companies, for example. It can take the form of a pallet covered in stretch film.

Choosing the right material for packaging

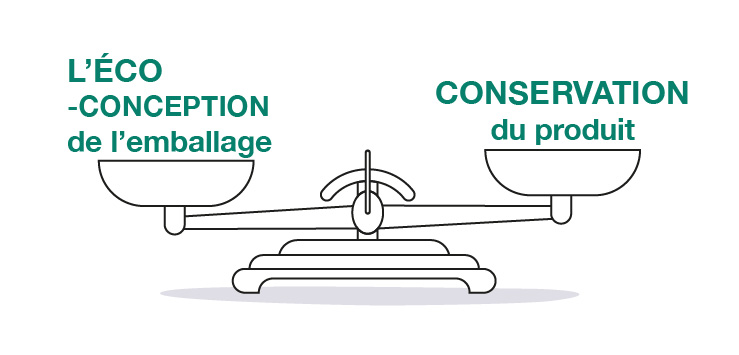

Before thinking about shape, think material. A liquid won't last long in a mono-layer paper bag. The first thing to do is to find the right material to protect your product.Why is the choice of material so important for your packaging ?

Do you want to convey an environmentally-friendly image or rely on a new type of packaging? Bear in mind that the primary function of packaging is to preserve, transport, and handle its contents. It is therefore essential to know the composition of your product and what it needs to be protected against (temperature, humidity, etc.).

Do you sell cosmetic creams or solid foodstuffs? Each product has its own specific chemical characteristics, so you can't choose just any material. Especially if the product is in direct contact with the packaging (primary packaging). You also need to consider regulatory storage requirements and your own requirements (odour, flavour, freezing, health standards, etc.), as well as the environment in which the product will be stored. Don't hesitate to work with a packaging solution expert who can find the right packaging solution for you expert de la solution packaging.

Different materials and barriers

Packaging is generally made up of several films bonded together, known as multi-layer packaging. The combination of different materials makes it possible to respond to physical and chemical constraints to protect the product contained. This process of assembling films is called laminating.

When it comes to packaging materials, there's plenty to choose from :

PE polymer, PP, biodegradable polymer: strong, practical, and good for preserving the product;

Aluminium: light, flexible, gas-tight, but limits the shape of the packaging ;

Glass: transparent, recyclable, and reusable, but fragile and only for solid packaging (bottles, flasks, etc.). ;

Tin-plate and chrome: especially for solid cans ;

Cardboard, paper, and wood: recyclable, flexible but more fragile and incompatible with liquid products.

You may need to incorporate barrier materials (EVOH, high barrier, etc.). Particularly resistant to gas and humidity, they are sometimes necessary. In particular, they enable the quality, flavour, and aroma of a product to be preserved for a long time. They are also used to protect the ink on a printing film.

Choosing the shape of your packaging

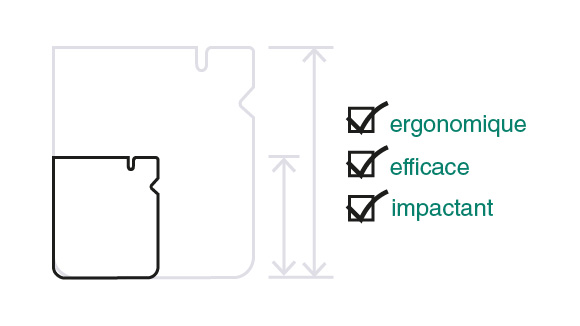

When it comes to packaging, shape is often the choice that involves the most risks: ergonomics, support, volume... and the one that can prove costly. Here's our advice on designing the right shape for your project!Key points about packaging format

With new 3D printing and digital sealing technologies, you have the freedom to let your imagination run wild to create unique packaging! Once the material has been determined, move on to the shape of the packaging. Have a custom prototype developed to reflect the image of your corporate brand. Would you like to give the packaging a specific, innovative shape? Do you want to stand out from the competition? A tailor-made design will be the best way to attract attention in-store or at a trade fair. But keep in mind to: d’impression 3D et de soudure digitale, vous pouvez laisser libre cours à votre imagination pour créer un packaging unique ! Une fois le matériau choisi, passez à la forme de l’emballage. Faites développer un prototype personnalisé afin de refléter l’image de votre marque d’entreprise. Vous souhaitez donner une forme spécifique et innovante à l’emballage ? Vous voulez vous démarquer de la concurrence ? Un design sur-mesure sera le meilleur moyen d’attirer les regards en magasin ou dans un salon d’exposition. Attention néanmoins à :

Think about practicality and ergonomics for the consumer experience (consider a product that is easy to use rather than one that is aesthetically pleasing). ;

Keep it simple and effective ;

Think about where the consumer will store it ;

Make it easy to transport ;

Design the right size ;

Consider the shape constraints associated with the choice of material.

Standard packaging shapes

Whether you're doing something simple or original, you need to base your packaging on a standard shape. If digital printing is used to bring all your ideas to life, you need to be familiar with the great packaging classics. Here are the most common in the industry :

The doypack or stand-up pouch ;

The three-seam pouch, sealed on three sides ;

The cushion pouch, sealed on four sides ;

The Berlingot pouch, with a tetrahedral shape

Choosing the right print for your packaging

The packaging is taking shape. All that's left is to give it your colours! Reproduce a personalised visual on the printing film using the process that suits you best. The choice depends on the quality of the result, the volume of prints, and your budget. Here are the main techniques :

- Digital printing: ink or laser, this high-quality method is easy to use and suitable for small production quantities ;

- Offset printing: fast and reliable, this technique is suitable for large production quantities ;

- Flexographic printing: this inexpensive process gives variable rendering results ;

- Screen printing: reliable and durable, this stencil-based technique can be used to print on any type of substrate, even directly on some food !

- Heliogravure printing: for top-quality results.

You now have all the information you need to choose the packaging that's right for you. Standard format, environmentally-friendly or original design, you can push back the boundaries of traditional packaging to win over consumers and maintain the quality of your products!