Created in 1963 by Louis Doyen, CEO of Thimonnier, a French company, the Doypack pouch has continued to rise in popularity since the latest regulations imposed on brands regarding their packaging Thimonnier.

What is a Doypack?

The origin of the word "Doypack" refers to the combination of "DOYen" (in reference to Louis Doyen) and "PACKaging.".

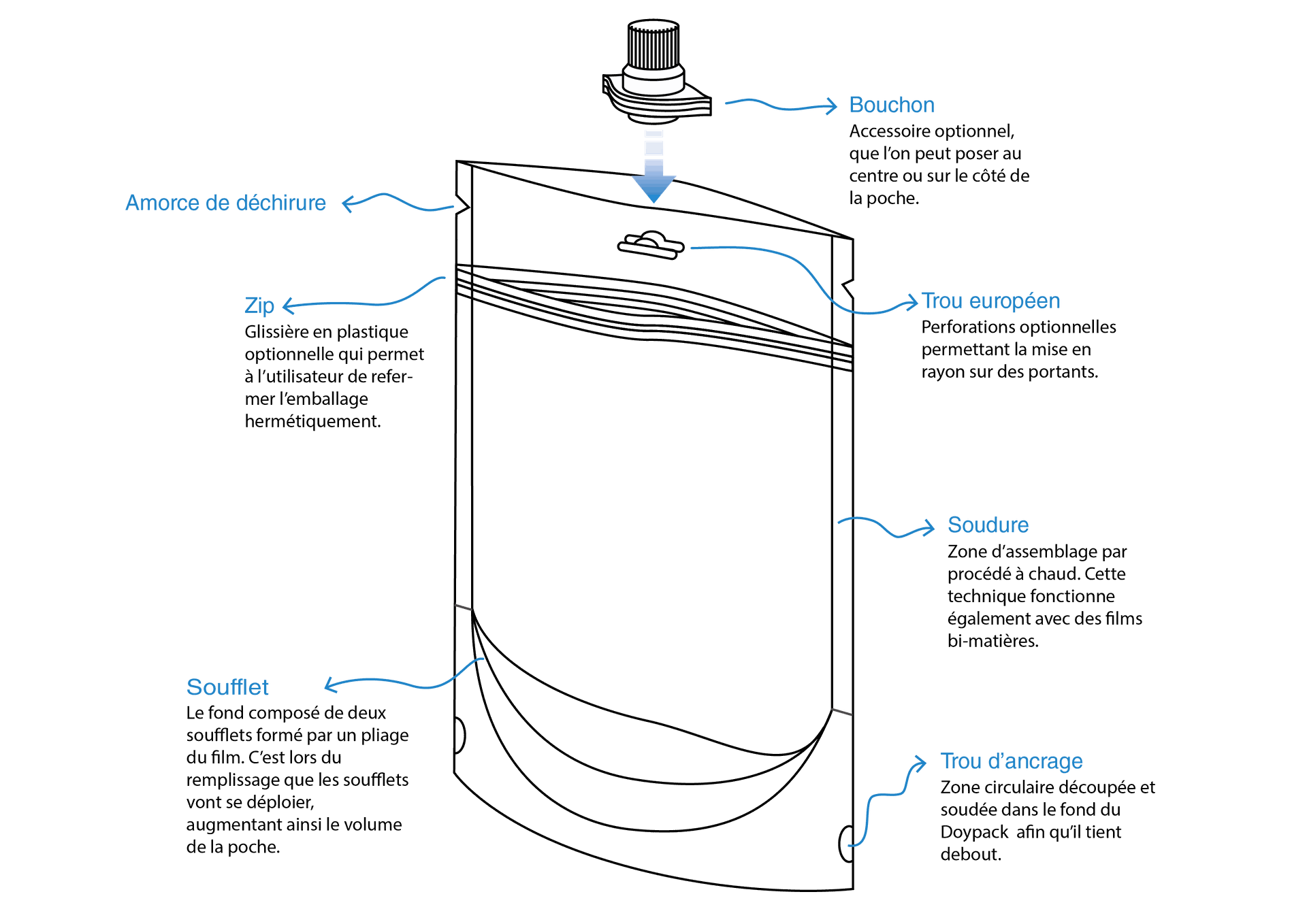

Also known as a stand-up pouch, its main characteristic is to stand upright without any support, thanks to the bottom it is made with. The bottom of this pouch can be in the shape of a "K" or in a smiley face shape (boat-shaped bottom) (see image). The main difference between these two types of bottoms lies in the aesthetic appearance of the final Doypack.

It can be designed with or without accessories; examples of these are spout and zip.

The spout on a Doypack is usually located at the top of the pouch, in one of the corners, or horizontally aligned along the upper side. As for the zip, it will be positioned at the top across the full width of the packaging. These accessories allow the pouch to be resealed when it still contains the product, thus ensuring proper preservation of the contents. This is referred to as a multi-dose option.

Why use a Doypack ?

Unlike a solid packaging, the Doypack pouch can contain up to about 80% less material in its construction, which is the case when comparing 2 bottles of 250ml each to 1 Doypack pouch of 500ml.

This reduction promotes space and weight savings during transportation as well as on the shelves where it is displayed.

There are other advantages to designing a Doypack as well. Indeed, a product can be fully packaged in this single packaging. This is referred to as primary packaging. The Doypack does not require secondary packaging because it is self-sufficient in both protecting the contained product and showcasing it with marketing and informational elements (printing or label) on the film. Let's take the example of the brand Pierre Fabre, which has developed a Doypack with a cap for toothpaste, as well as C'leene, which has opted for an eco-refill Doypack for its toothpaste: there is no unnecessary packaging .Pierre Fabre qui a su développer un Doypack avec bouchon pour du dentifrice, ainsi que C'leene qui a opté pour un Doypack écorecharge pour son dentifrice : il n’y a pas d’emballage superflu.

What can a Doypack contain and what is it made of?

A wide variety of products, each different from the others, can be contained within this type of packaging. Whether it's a liquid food product (liquid cream) or a cosmetic product (shampoo, oil), a powder (sugar, shower gel), or even capsules (dietary supplements), it simply requires adapting the material that makes up the pouch. Each material offers different barriers to best match the protection the product requires. Most often, these barriers include protection against oxygen, moisture, gases, and UV light.

There are multi-layer materials, both recyclable and non-recyclable. To determine their recyclability, it's enough to pay attention to the symbols marked on the Doypack, often located at the back of it inscrits sur le Doypack, souvent installé à l’arrière de celui-ci.

For plastics, there is the monomaterial polyethylene, known as Mono PE. It is the most recycled material in France in the yellow bin.

It is also possible to create Doypacks using paper, using composite materials such as brown or white Kraft paper, as well as apple paper composite. Flexible paper-based packaging can include a thin layer of plastic on the inside. Laminating these two materials allows the product to be protected and also protects the packaging of the product. In France, the recyclability of this type of material is possible as long as the paper fiber content is above 50% (unlike our neighboring countries where the minimum mass percentage of paper fiber content in packaging must be above 80%).

How to fill a Doypack pouch ?

Two types of filling exist :

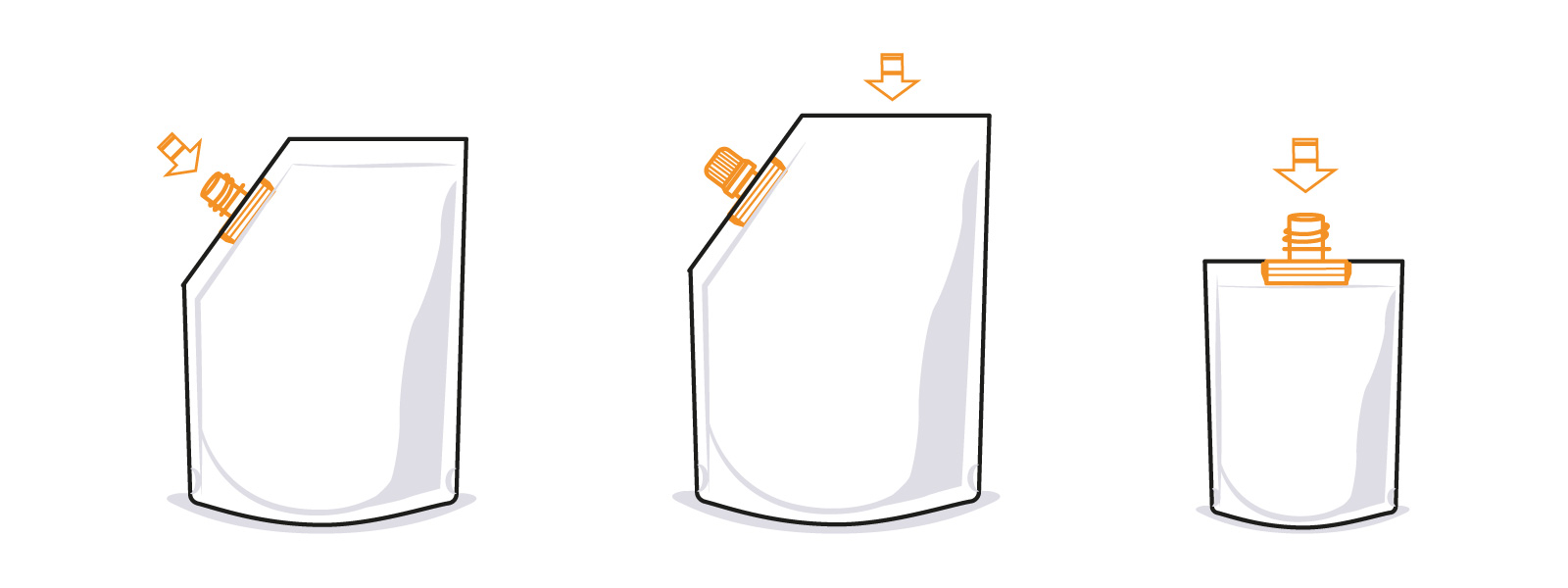

- Filling Doypack pouches through the spout.

As the name suggests, the product enters the pouch through the packaging's cap. This means that the packager receives fully sealed pouches. It will then only be necessary to permanently close the packaging. For this type of packaging, a cap is specifically designed, known as a "cap with a guide".

- Filling from the top of the pouch

The packaging is received by the packager with the top of the pouch unsealed. The bagging machine opens the pouch, inserts the product into the packaging, and then reseals it using heat sealing or ultrasonic sealing.

It is also possible to package your packaging manually, using a semi-manual or automatic filler. The choices for sealing the Doypack, after packaging, remain the same.

If the filling is done from the top of the pouch, you will need a welding device in order to reseal the pouch.

If the pouch is fully sealed and the filling was done through the cap, then you just need to close the cap to complete the packaging.

The Doypack Sealester creations

Sealester produces innovative and eco-designed Doypack pouches, both with and without accessories

We specialize in creating flexible packaging for sectors such as cosmetics, food and beverages, well-being, home care, and many others!

Our sealing technology enables us to develop and enhance the use of pouches for consumers, even to the extent of creating new applications..

For example, for single-use refills, we have observed that brands primarily use the spout for its ability to transfer the product to another container..

It is in this direction that we work and develop spouts tailored to the products and the container to be filled. Thanks to this, users have a positive experience with the use of the refill, while reducing the amount of plastic used in it..

Always seeking to enhance the use and practicality of these bags, projects related to their ergonomics are consistently present in Sealester's innovations.