A key element in the design of a product intended for sale and its acceptance by consumers, packaging is often neglected by brands. A product's second skin, packaging design represents a brand's values and identity, fundamental factors in the customer's decision to buy. What is packaging design? How do you design innovative packaging? What are the new challenges in the sector? Sealester explains.

What is packaging design?

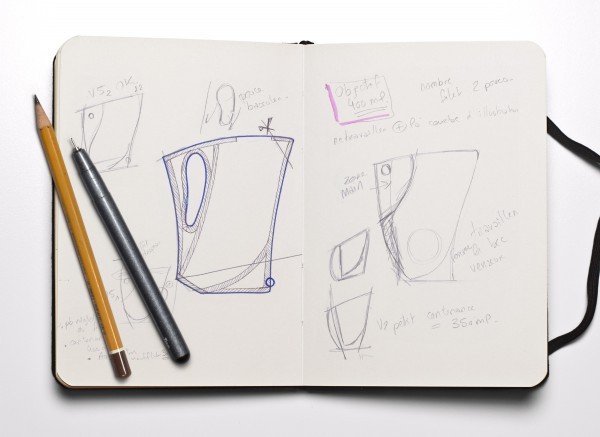

Packaging design is the creative and technical phase of conceiving the volumes, decorations, and materials of a packaging intended to contain a commercial product. The design is carried out internally or externally, by a team of packaging designers specialising in the task

Based on a set of specifications, i.e., a list of fundamentals to be respected defined by a company, a team of creative designers conceives the various parts of the design, including :

Structural design: corresponding to the direct form that the container will take, in line with its purpose,

Graphic design: corresponding to what will be printed on the surface of the container to inform the consumer about the product.

Sealester works to develop packaging with innovative and non-standard designs. Our aim is to accompany our customers further in their vision of packaging and to conceptualise real marketing tools that will support brands in their growth.

The phases of packaging design

The twenty-second rule is well known in marketing and especially in packaging design. It is in the first twenty seconds that the consumer decides whether or not to buy a product. So, the packaging, its materials, its design, its visual information, and its ergonomics are discussed at length by the creative teams, during several phases. These are described below.

Creative briefing

During the first phase, also known as the creative briefing, the teams of designers meet the customer and discuss the project and the collaboration. The company then sends a brief and a graphic charter on which the designers base themselves to establish the feasibility of the project, the customer's wishes, and the budget

It is during this phase that artistic and practical choices are made concerning :

- functionality,

- choice of materials,

- ergonomics,

- aesthetics,

- the product's universe

- the specific nature of the offer,

- the target audience,

- the sales interface (internet and/or boutique),

- poly-sensoriality,

- usage,

- environmental friendliness,

- packaging standards,

- shipping requirements.

This more artistic part is carried out under the influence of marketing. It will touch on the emotional aspect of the product, its aura, and its image for potential buyers.

Most products have three parts :

- the inside of the packaging in direct contact with the product,

- the outside of the packaging, which contains information and graphic identity,

- the shape of the packaging itself.

There can be more than one type of packaging for the same product. In such cases, the primary packaging is that in which the product itself is contained, such as a tube of toothpaste. The primary packaging is then incorporated with the secondary packaging in which the product is wrapped for sale: the cardboard box around the tube of toothpaste. The third packaging can be used to prepare a parcel for postal delivery.

Sealester designs primary packaging that also acts as secondary packaging. A cereal pack that is both flexible and strong, protecting the product from the outside world while clearly displaying the packaging information. Or an environmentally-friendly refill, so that you don't have to buy solid packaging again and can simply refill the one you keep after the first purchase. The aim is to reduce the use of resources through innovative materials and technologies.

Choosing the right materials

The choice of materials is central to design. We are at a time when more and more shoppers want to ban polymer from their consumption. We also must consider the AGEC law against waste and supporting the implementation of a circular economy. Single-use polymer products are to be phased out by 2040, there is no longer any justification for offering polymer as THE solution. The future of packaging is intimately linked to the industry. That's why we want to play an active role in promoting responsible and Made in France: central elements towards sustainable development that we incorporate in the development of environmentally-friendly products and environmentally-friendly refills for food, cosmetics, luxury goods and wellness.

A common vision of a future that is aware of the new social paradigms that we share with the sector and our suppliers. Corrugated cardboard, edible packaging, compostable polyethylene based on corn starch... there are many solutions. Sealester works with an innovative and constantly evolving library of materials. PE kraft composite, apple fibre paper, PE metallised paper and transparent paper composite are at the heart of our products.

In the second phase, the supplier's point of view is combined with the teamwork of the customer and the manufacturer, to find a concrete, economical, and responsible solution for the design of the product packaging.

The test and production phase

In this phase, the first prototype is produced with a series of usage, weight, and functionality tests, to make sure that the packaging is not just aesthetically pleasing, but also practical and interesting from a quality-price point of view. Once the prototype is complete, the teams send it to the customer for approval or to make any final changes. This phase, also known as prototyping, precedes the production phase of the product in mini, small, and medium batches, which Sealester also handles.

The Sealester difference

We keep abreast of the latest technical and technological advances and recycling standards in different countries, so that we can offer ever more innovative, cost-effective and environmentally-friendly tailor-made packaging solutions. This is the case with our digitally-sealed or trifacial packaging, which breaks the mould with an ecological approach that uses fewer raw materials. Find out more about our latest breakthroughs.